Investment Casting Shell Drying System with Microwave

Advantages & Key Features

■ Super Fast Dry

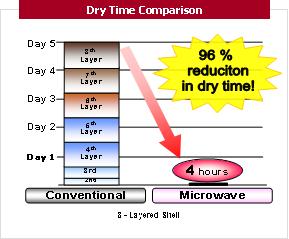

■ Super Fast Dry ・ Drastic lead time reduction in lost wax shell production.

( 5 days to 4 hours - 96% reduction rate )

・ Wax temperature kept low - approximately 25C ( 77F).

■ No Shell Cracks.

■ Numeric Dryness Measurement with Shell Weight Change.

( PATPEND)

■ Both Normal and Special Slurry Applicable.

■ Flexible Application.

■ Simple and Easy Operation.

Dry Shells in Short Time - Only 30 Minutes per Layer

Whereas with conventional methods of shell drying it takes approximately 2 - 3 hours for the 1st and 2nd layer, 3 - 4 hours for 3rd - 5th layers, and 4 - 8 hours for the following layers, Japan High Comm Microwave furnace dries shells only in 30 minutes per layer.

Whereas with conventional methods of shell drying it takes approximately 2 - 3 hours for the 1st and 2nd layer, 3 - 4 hours for 3rd - 5th layers, and 4 - 8 hours for the following layers, Japan High Comm Microwave furnace dries shells only in 30 minutes per layer.Applications

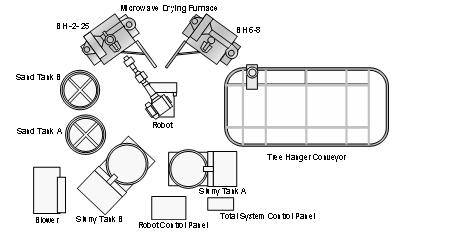

Application Example 1: Full Automatic

- Suitable for Large Item Small Volume Production -

- Suitable for Large Item Small Volume Production -

Layout

Operation Procedure

> Unload mold tree from conveyor with robot.

> Dip mold tree into slurry and coat sand.

> Put mold tree into multiple microwave drying furnaces by turns.

> Take out mold tree from microwave drying furnace.

> Unload mold tree from conveyor with robot.

> Dip mold tree into slurry and coat sand.

> Put mold tree into multiple microwave drying furnaces by turns.

> Take out mold tree from microwave drying furnace.